UK battery developer Britishvolt has selected China’s BTR to supply synthetic graphite and silicon oxide to its proposed UK gigafactory in Blyth, Northumberland, it said July 28.

BTR will manufacture the anode material with renewable hydroelectricity and intends to establish a sustainable footprint for manufacturing in Europe, the company said.

BTR's global strategy about manufacturing location and upstream material plans would also be attractive to the UK battery developer, British Volt Global COO Timon Orlob said in a statement.

“We have always been focused on global supply chains, and with this collaboration with BTR we are realizing that,” he added.

Speaking from the fringes of the Alcantara event on, industry sources from BTR have confirmed that, whilst the company is based in China, the intention was to shift BTR supply from over the water and into the EU as factories were commissioned and production ramped.

That would make supply chains shorter, leading to less embedded carbon, and enable British Volt to establish an ecosystem in which component makers are based close to the assembly plant, he said.

“It is reducing our carbon footprint, so we plan to localize suppliers closer to our manufacturing plant, which is based in northeast England,” Kilbey said.

Synthetic graphite was initially selected by the battery developer, as it offered superior electrochemical performance advantages over natural graphite in some chemistries, said Ben Kilbey, Luminous CEO.

“British Volt is also exploring natural graphite where that makes sense,” he added.

Synthetic graphite has strikingly outweighed the environmental highlight tab as a by-product of petcoke, but Kilbey revealed that 12% of the average carbon footprint of synthetic graphite produced was generated through petcoke, while 82% came from the process of production.

“Well, as we know, synthetic graphite is an energy-intensive process, so I mean with the switch to hydroelectricity, this is going to allow us to, I would suggest, have the biggest impact (in reducing our overall carbon footprint),” he said.

British Volt has already locked down several other battery materials, including cobalt with strategic partner Glencore, nickel sulfate from a joint venture with Indonesia's VKTR and cathode and anode active materials with Posco Chemical.

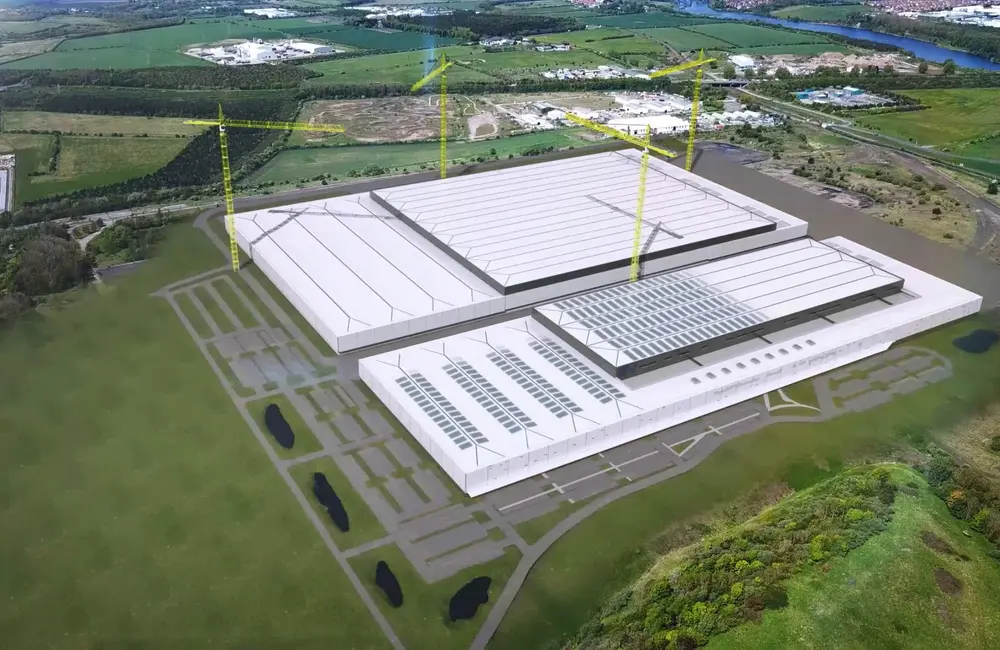

The battery developer is currently building its GBP3.8 billion ($4.6 billion) gigafactory, which will be made up of four 10 GWh phases, after it broke ground on the site in September 2021, with the first phase targeted to begin production in 2024.

It is also set to develop a second 60 GWh gigafactory in Quebec and in discussions with the Canadian government over its expansion plans.

The increase in demand has lifted battery metal prices overall in 2022, with seaborne lithium carbonate and lithium hydroxide assessments climbing 111.2% and 136.6%, respectively, since the beginning of 2022 to $71,400/mt CIF North Asia and $75,000/mt CIF North Asia on July 27, 2022, according to data.